How to choose titanium dioxide pigment for powder coating?

Abstract: Powder coatings have good environmental properties and excellent coating results. This article introduces how to choose titanium white pigments suitable for powder coatings. It is recommended to consider the following properties of titanium dioxide: (1) the type of titanium dioxide; (2) the surface treatment of titanium dioxide; (3) the particle size distribution of titanium dioxide; (4) pH value of titanium dioxide; (5) water content of titanium dioxide.

Part 1: Introduction

With the increase of environmental protection in China, the coating industry has gradually developed into high-solids coatings and water-based coatings. Powder coatings are representative of solvent-free high-solids coatings[1], and their volatile organic compounds (VOC) emissions are much lower than traditional solvent-based coatings. Some products have achieved zero VOC emissions; It is an environmentally friendly coating that produces little solid waste during the coating process and prevents air pollution and fire.

Powder coatings are made by uniformly mixing polymers such as polyester resin, polyurethane, polyacrylic acid, and epoxy resin with pigments, additives, etc. [2]. Powder coatings are easy to construct, generally only need one coating to meet the requirements of use. In the case of excellent coating process control, the film does not produce pores, acid and alkali resistance, corrosion resistance; powder coating equipment volume Small, small footprint, comprehensive investment of complete sets of equipment is smaller than traditional solvent-based coatings; powder coatings are not flammable, safer, convenient, simple and economical in use, storage and transportation; oversprayed coating powder can also be recycled and reused; Powder coatings have received extensive attention since the invention due to the above advantages. The coating process of powder coating can be divided into powder fluidized bed coating method, electrostatic spraying method, electrostatic oscillation method, currentized bed method, low-capacity electrostatic cloud chamber method, powder electrophoresis method and flame spraying method. The electrostatic powder coating method is currently the most widely used due to its high powder utilization rate, easy automation, and smooth coating on both the tip and the rough surface of the workpiece. Industries mainly based on powder coating include furniture manufacturing, home appliance kitchen manufacturing, steel pipe industry, automobile industry, agricultural machinery industry, fire equipment, motor industry and construction industry.

Part 2: The natrure of titanium dioxide

The main component of titanium dioxide is TiO2, which is the best white pigment pigment [3-7]. Because of its higher refractive index, the ability to deflect light is greater than other white pigments, so it has better hiding power in coating applications. The refractive indices of common white pigments are shown in Table 1. The coating function prepared by titanium dioxide covers the substrate, beautifies the substrate, protects the substrate, and avoids the rust and corrosion of the substrate by the influence of light, heat and moisture. All in all, the basic performance of titanium dioxide in the industry is “coverage-beautification-protection”.

| Material | Refractive index | Material | Refractive index |

|---|---|---|---|

| Titanium Dioxide Anatase | 2.71 | Basic lead carbonate | 2.00 |

| Titanium Dioxide Rutile | 2.52 | Basic lead sulfate | 1.93 |

| Zinc sulfide | 2.37 | Barium sulfate | 1.64 |

| Zinc oxide | 2.02 | Talcum powder | 1.57 |

Part 3: The important role of titanium dioxide in powder coatings

In the formulation design of powder coatings, the combination of resin and cross-linking agent is regarded as the direction that must be considered in the main performance of powder coating; therefore, the development of resin and cross-linking agent is devoted. But this does not mean that titanium dioxide is not so important, you can adjust and replace it.

Titanium dioxide has an impact on the production, coating and film properties of powder coatings. In the production process, the dispersion of titanium dioxide directly affects the mixing effect, and also affects the dispersion of hot melt and the level of productivity in the extrusion processing. During the heat curing of the coating film, the surface properties of the titanium dioxide also affect the fluidity of the hot melt, the hardening speed and the yellowing which occurs during excessive baking. In terms of coating film performance, titanium dioxide affects the hiding power, gloss and weather resistance of the coating film.

Therefore, when developing powder coatings, consider how to choose the right titanium dioxide. When using titanium dioxide, it is recommended to consider the following properties of titanium dioxide:

(1) the type of titanium dioxide

(2) the surface treatment of titanium dioxide

(3) the particle size distribution of titanium dioxide

(4) the pH of titanium dioxide

(5) titanium dioxide Water content

Types of titanium dioxide

Commercial titanium dioxide can be divided into two categories: anatase and rutile titanium dioxide. The crystal characteristics and physical constants of titanium dioxide are shown in Table 2. Due to the difference in chemical structure, although it belongs to titanium dioxide, its performance is different. The coating is made of anatase titanium dioxide, which is prone to chalking in daylight. Compared with rutile titanium dioxide, the powdering resistance is better. Therefore, in the selection of titanium dioxide category, it is recommended to use rutile titanium dioxide.

| Physical properties | Titanium dioxide rutile | Titanium dioxide anatase |

|---|---|---|

| Crystal system | Tetragonal | Tetragonal |

| Crystal shape | Needle shape | Cone shape |

| d(μm) | 0.2-0.5 | 0.1-0.5 |

| Relative density | 4.2-4.3 | 3.8-3.9 |

| Refractive index | 2.71 | 2.52 |

| Moh's hardness | 6-7 | 5.5-6 |

| Melting point | 1858℃ | 915℃ trun to rutile |

| Cal/g.℃ | 0.17 | 0.17 |

| UV absorption rate(%) | 90 | 67 |

| Hiding power | 30.1 | 23.6 |

| Tinting strength Reynolds | 1650 | 1270 |

| Lattice constant | a=0.459, c=0.296 | a=0.378, c=0.951 |

Surface treatment of titanium dioxide

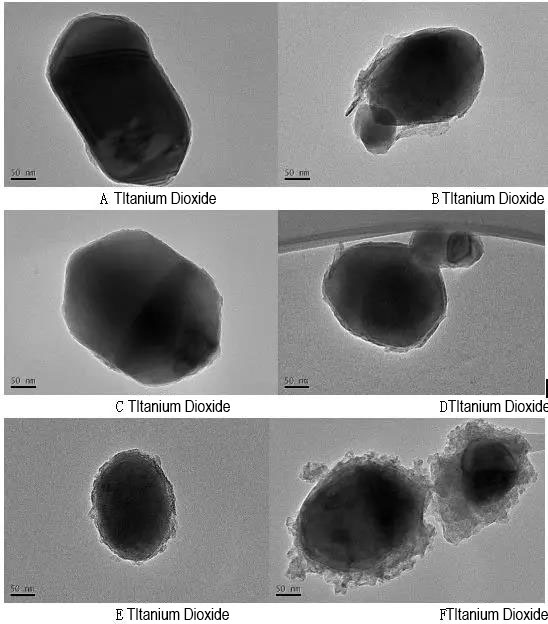

In order for titanium dioxide to perform its special functions under different powder coating systems, different surface coating treatments must be carried out in the production of titanium dioxide. For example, in order to express dispersibility, gloss is treated with hydrated alumina (aluminum hydroxide); in order to enhance weather resistance, surface treatment of hydrated silica and hydrated zirconia is performed. In order to enhance the wetting effect and the fluidity of the production, an organic surface of a polyol, an amine or a silane or a silyl ether is used.The whiteness of titanium dioxide is determined by the content of titanium dioxide in titanium dioxide; the more the surface treatment agent, the lower the content of titanium dioxide in titanium dioxide, thus affecting the whiteness of titanium dioxide. Therefore, it is desirable to have a higher whiteness when the powder coating film is applied, and it is more suitable to use a titanium white powder having a lower surface treatment agent content.In addition to the resin and formulation design, the surface coating of titanium dioxide also plays a supporting role.The surface coating treatment of alumina contributes to the dispersion of titanium dioxide in the resin system, thereby enhancing the optical properties of the titanium dioxide in the resin system, such as gloss, hiding power and the like. The crystallinity of alumina itself also contributes to the improvement of gloss. To design a semi-gloss or flat coating, choose a titanium dioxide powder with a silica treatment on the surface.Commercially available titanium dioxide has a surface treatment of alumina and silica. According to the functionality of gloss, there are so-called high-gloss titanium dioxide, glossy titanium dioxide and flat-light titanium dioxide.There are two ways to surface coat the silicon oxide.One is a loose adsorption type; after treatment, the surface structure is loose, the powder has a large particle size, the effective surface area is increased, and the oil absorption is high. In terms of functional performance, due to its loose structure, avoiding excessive crowding and creating a spatial effect, it contributes to the improvement of dry film hiding power.The other is a surface treatment of precipitation type; this method is to coat the silicon oxide tightly around the periphery of the TiO 2 particles, like a colored sugar coating outside the chocolate candy.Because of its compact structure, the structure of active titanium ions on the surface of TiO 2 and the polymer of the external environment are reduced, so that it does not cause yellowing, fading or chalking.Therefore, titanium dioxide can be divided into outdoor high weathering titanium dioxide and indoor titanium dioxide according to the degree of weather resistance. The TEM image of titanium dioxide coating without application is shown in Fig. 1.

The characteristics of titanium dioxide can be distinguished from the treatment of surface coated oxides. However, the detailed surface coating chemical and structural properties must be discussed with relevant scientific and technical personnel to further understand how to select the appropriate titanium according to product design. White powder.

Particle size distribution of titanium dioxide

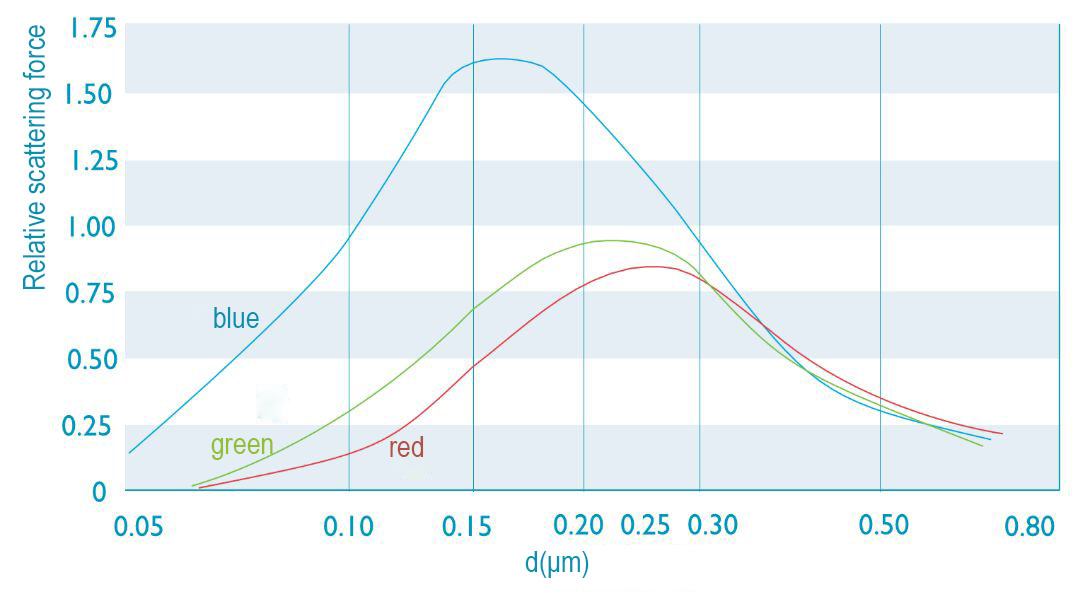

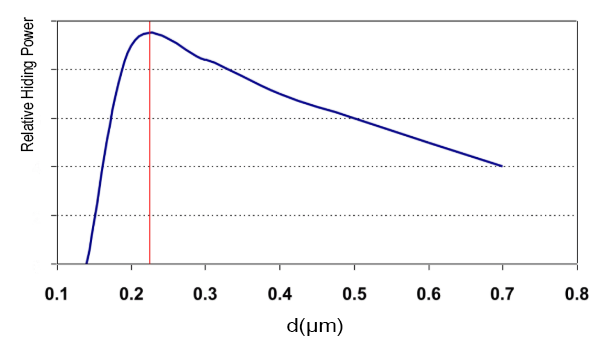

The particle size of titanium dioxide determines the color tone of the film.Titanium dioxide is produced in order to produce optimum optical properties, often with particle sizes around 0.2 microns and particle size distributions from 0.15 to 0.3 microns. The smaller the particle size of titanium dioxide, the greater the degree of deviation of blue light, so the coating film will show a “blue-white” hue; if the particle size is larger, the hue tends to “yellow white”. Particle size and discoloration force are shown in Figure 2.However, sometimes the titanium dioxide powder is yellowed because the purification process is not ideal at the time of manufacture, and coloring impurities such as vanadium ions or iron ions remain in the titanium dioxide.Therefore, in the production of powder coatings, if a special hue is specified, it is recommended to pay attention to the particle size and distribution of titanium dioxide. In addition to the dispersion of titanium dioxide affects the coverage, the particle size of titanium dioxide also affects the hiding power, the trend is shown in Figure 3.

The pH of titanium dioxide

The pH value of titanium dioxide generally has a significant effect on waterborne coatings; it affects the performance of system dispersants and tackifiers. Powder coatings must be considered depending on the free acid concentration or accelerator type of the resin selected.In the general acid-catalyzed process, the titanium powder with a high pH value neutralizes the catalyst, so that the hardening is incomplete and the hardness of the coating film is lowered.Titanium dioxide with a low pH value will accelerate the acid catalyzing effect, making the coating film harden too fast, which may easily cause surface defects of the coating film. Generally used at pH 7-8 is more suitable.

The water content of titanium dioxide

Titanium dioxide powder will absorb some of the moisture in the environment, resulting in an increase in water content.The increase of water content of titanium dioxide powder will cause poor dispersion, poor fluidity, bridging the conveying pipeline, and the surface of the coating film will easily cause wrinkles, pinholes, fisheye and other defects.The degree of adsorption of moisture by titanium dioxide is related to the concentration of the surface treatment agent. Generally, the titanium dioxide with high treatment content has a higher moisture absorption degree.Therefore, when storing materials, it is best to control the temperature and humidity of the environment. It is recommended that the warehouse temperature not exceed 27 ° C, the relative humidity does not exceed 75%, in order to avoid the risk of “powder dust explosion”, the facilities of the ventilation equipment can be strengthened to maintain air circulation and reduce indoor dust concentration.It is recommended that the water content of the powder (including titanium dioxide, filler and other powders) should not exceed 0.5%.

Part 4: Method for evaluating the suitability of titanium dioxide in powder coatings

Titanium dioxide, like other raw materials, does not allow for all of the design requirements. It can be fully expressed in some characteristics, but it may have negative effects in other aspects, so the characteristics of the product must be considered when selecting titanium dioxide. In the evaluation of whether titanium dioxide is appropriate, it is often divided into three major properties to compare:

- Powder properties include: fineness distribution of powder, powder fluidity, gelation activity.

- The optical performance of the coating film includes: color, hiding power, gloss (20°, 60°), and degree of yellowing of excessive baking.

- Mechanical properties of the coating include: hardness test, solvent resistance test, flexibility test, impact test.

Part 5: Conclusion

Powder coating formulation design is often adjusted according to different needs.Resins, bridging agents, pigments, fillers and other additives are common in basic formulations. Titanium dioxide is also an important component in powder coatings. I hope that the narrative of this article can provide another perspective for research and development in the coating and titanium dioxide industries. For the production of titanium dioxide, the development of new titanium dioxide products, the application of titanium dioxide products in powder coatings has reference significance.

Reference:

[1] Jiang Wenqi.Progress in green coating research [J].2009,36(5):68-69. Guangdong Chemical Industry, 2009, 36 (5): 68-69.

[2] Lin Ling, Zhou Bin. Powder coating overview [J].2012,39(2):79-80. Guangdong Chemical Industry, 2012, 39 (2): 79-80.

[3]Chen Chaohua, Liu Changhe. Production and application technology of titanium dioxide [M]. Beijing: Chemical Industry Press, 2005: 28-72

[4] Deng Jie, Wu Lifeng. Handbook of Titanium Dioxide Application [M]. Beijing: Chemical Industry Press, 2005: 1-35

[5] Genyao Zong, Modern water-based paint process, formulation and application [M]. Beijing: China Petrochemical Press, 2013: 186-198

[6] Wang Yunhua, Li Haiyan, Zhang Xiaoying, Wang Lei, Li Baojin, Long Xiang.Study on the effect of post-treatment process on the properties of rutile titanium dioxide in chlorination process[J].Inorganic Salt Industry,2015,47(3):16-18

[7] Lai Zhuen, some problems in the theory and technology of titanium dioxide application [C] Proceedings of the 2007 National Titanium White Industry Conference

Author: Yang Zhen, Kunming Institute of Metallurgy中文原文

Translated by: Chao.h, Tinox Chemie GMBH

How to choose titanium dioxide pigment for powder coating?

https://tio2.info/2019/08/09/How-to-choose-titanium-dioxide-pigment-for-powder-coating/